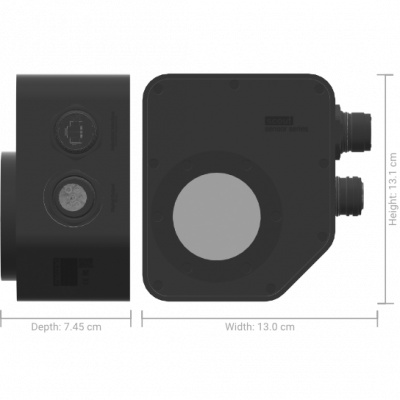

Mecorad Radar Sensor

Learn more and take your production to the next level.

Mecorad Radar Sensors: Your Key to Flawless Hot Metals Forming!

In the world of hot steel and metal processing, Mecorad Radar Sensors are your go-to solution. We've tailored our cutting-edge technology to meet the unique challenges of this dynamic environment.

🎯 Tailored Accuracy for Your Needs:

- In industrial settings, precision matters. Mecorad Radar Sensors provide spot-on measurements, ensuring accuracy even in the toughest conditions.

🌦️ Conquering Environmental Challenges:

- Whether it's dust, steam, heat, or a vacuum, our radar sensors stand strong. Unlike ultrasound or laser methods, our technology remains unaffected by external factors, guaranteeing consistent and accurate results.

🛡️ Safe and Reliable Technology:

- Forget the risks associated with isotopic solutions like X-ray. Mecorad Radar Sensors prioritize safety, creating a secure working environment for both equipment and personnel.

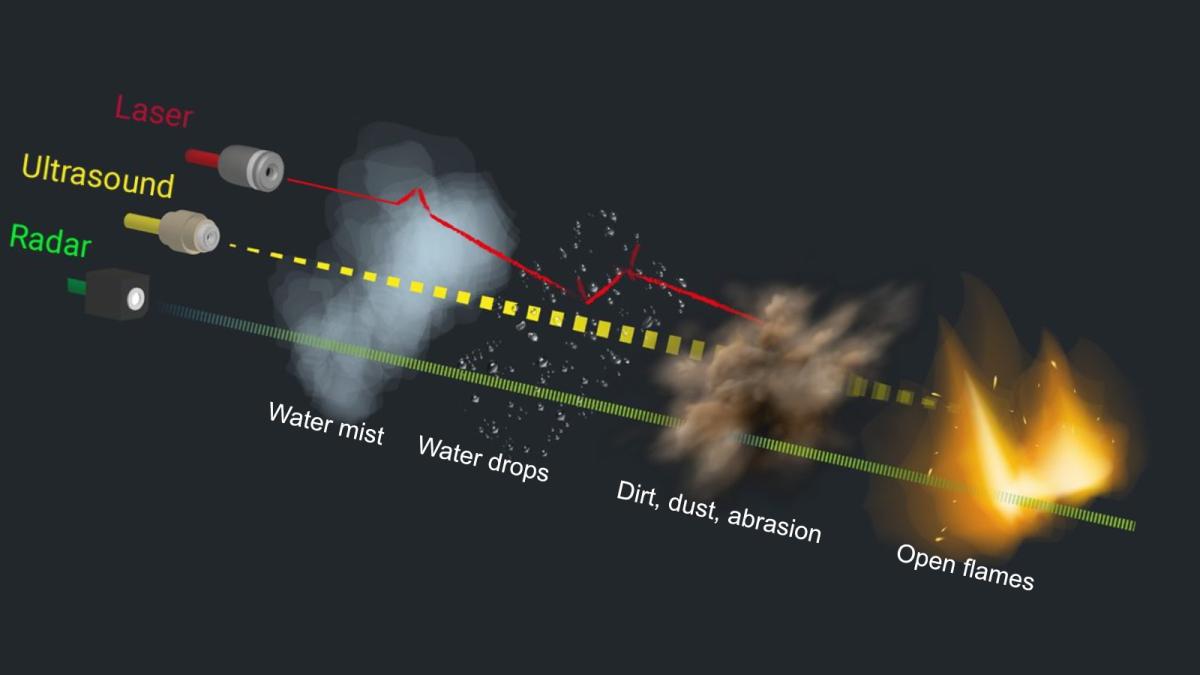

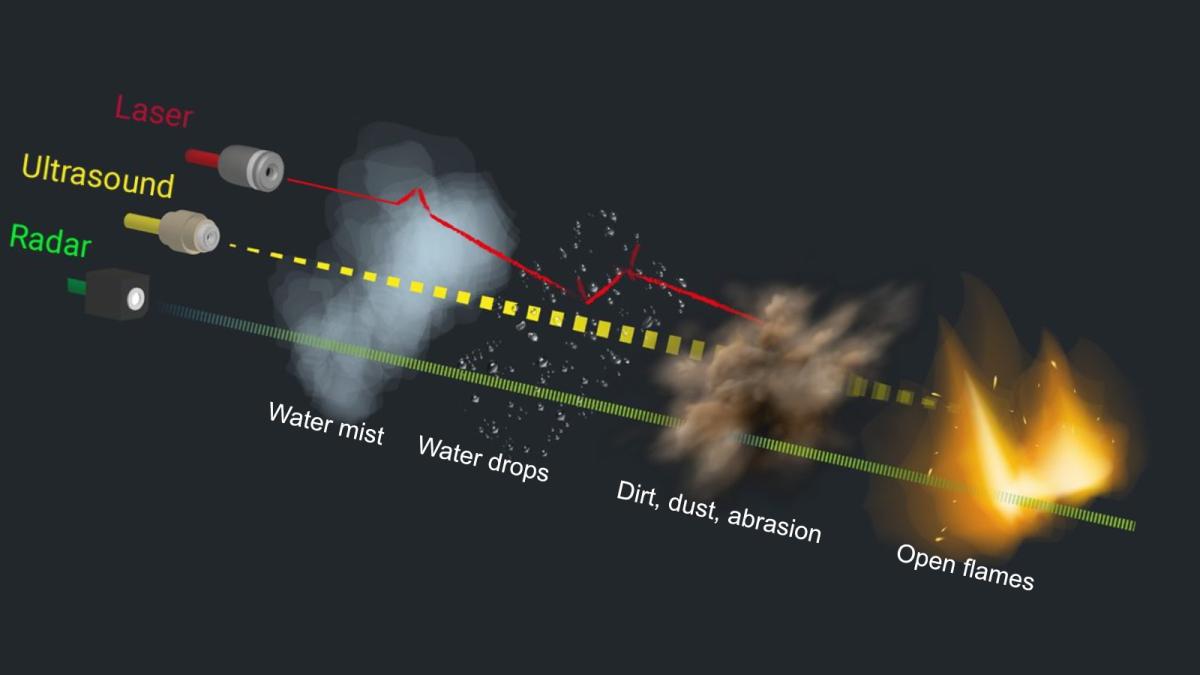

📏 Radar vs Ultrasound and Laser:

- Ultrasound: Struggles in heterogeneous environments. Dust, steam, and heat disrupt measurements, making it less suitable for industrial metal processing.

- Laser: Precision under specific conditions, but hindered by dust or deposits. Mecorad Radar Sensors outshine these limitations, providing a reliable alternative.

- Radar: Based on electromagnetic waves, it outshines the competition. Unfazed by adverse conditions, radar emerges as the superior choice for real-world industrial applications.

Empowering Industry 4.0 with IIoT Solutions: Mecorad integrates radar technology into innovative IIoT measurement solutions, enhancing efficiency and accuracy in industrial processes.

- Effective PLC Communication: Ensures seamless data exchange with programmable logic controllers (PLC).

- Advanced Connectivity: Additional COM package facilitates information dissemination using TCP/IP, REST, or MQTT interfaces.

Our Tailored Solutions:

- Distance Series: Real-time radar distance measurement of hot or cold steel.

- Level Series: Designed for extreme conditions above a mold, tundish, or ladle.

- Wtl Series: Two-sensor self-calibrating solution for width, thickness, and angle/skew measurements.